Discover our know-how in precision and micro-mechanics

More than 60 years of experience in design and construction of press tools.

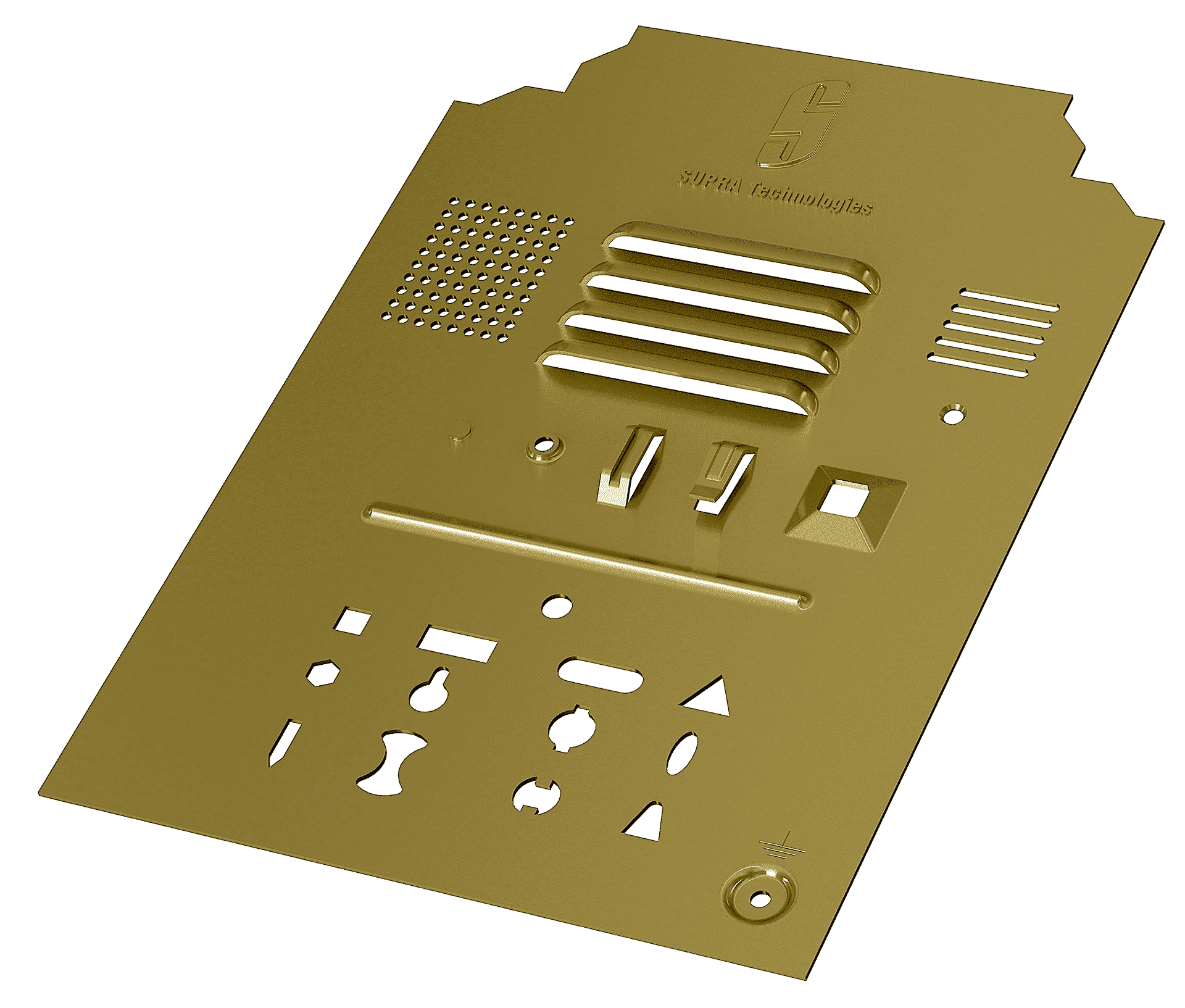

SUPRA Technologies offers a very wide range of punching, notching, cutting and shearing units recognized worldwide.

A multidisciplinary team is at your disposal and available to offer you the best solution.

SUPRA Units

Definition

Punching units are tools capable of performing unitary punching, notching or cutting-off work in sheet metal, profiles or tubes.

SUPRA units can be used on presses, press brakes of any type or in assembly integrating pneumatic, hydraulic, oleopneumatic or electric energy.

The SUPRA unit is the economical and rational solution adapted to all your manufacturing problems for medium and large series and repetitive parts.

Description

The SUPRA units consist of a body whose function is to provide the geometrical link between the punch and die. The punch holder is supplemented in the punching and notching units by a stripping assembly.

Setting up

The SUPRA units, thanks to their universality and their autonomous mobility, do not need to be attached to the upper part of the unit (except the units type PAL, PAEL and TT). Their positioning is ensured by a Ø8 pin located under the base plate in the punching axe.

Functioning

As the SUPRA unit is attached to the press table, the adjustment of the press ram closure or the adjustment of the bottom dead center (HOF) is of high importance. This rating is given for each unit. The unit is thus ready for use. The nose of the press come sinto contact with the striking plate. At the unit level, the sequence of operations is as follows :

- Descent of the press

- Bending of the ascent springs

- Contact of the stripper on the sheet metal

- Bending of the stripping springs

- Punching

- HOF reached

- Press pick-up

- Stripping the punch

- Raising the set

The punch is not integral with the slide, the body of the unit is not subjected to any mechanical stress.

Recommendation and maintenance

Set your press low dead point (HOF). This must in no case be less than the HOF indicated by the unit concerned or on the tool identification plate.

- The HOF must be checked periodically in fonction of the cadence and time.

- Check the condition of your punches and dies regularly (no wear and defects).

- Punches and dies must be sharpened regularly. Grinding 1/10 of the cutting faces, without waiting for a defect to appear, increases the longevity of the tool.

- After sharpening, the elements must be demagnetized.

- Carefully check the clearances between punches and dies. The clearances are adapted to the thickness and grade of the material.

- Regularly check that all components are securely fastened.

- Keep the tool clean.

- Periodically grease all moving parts of the tool.

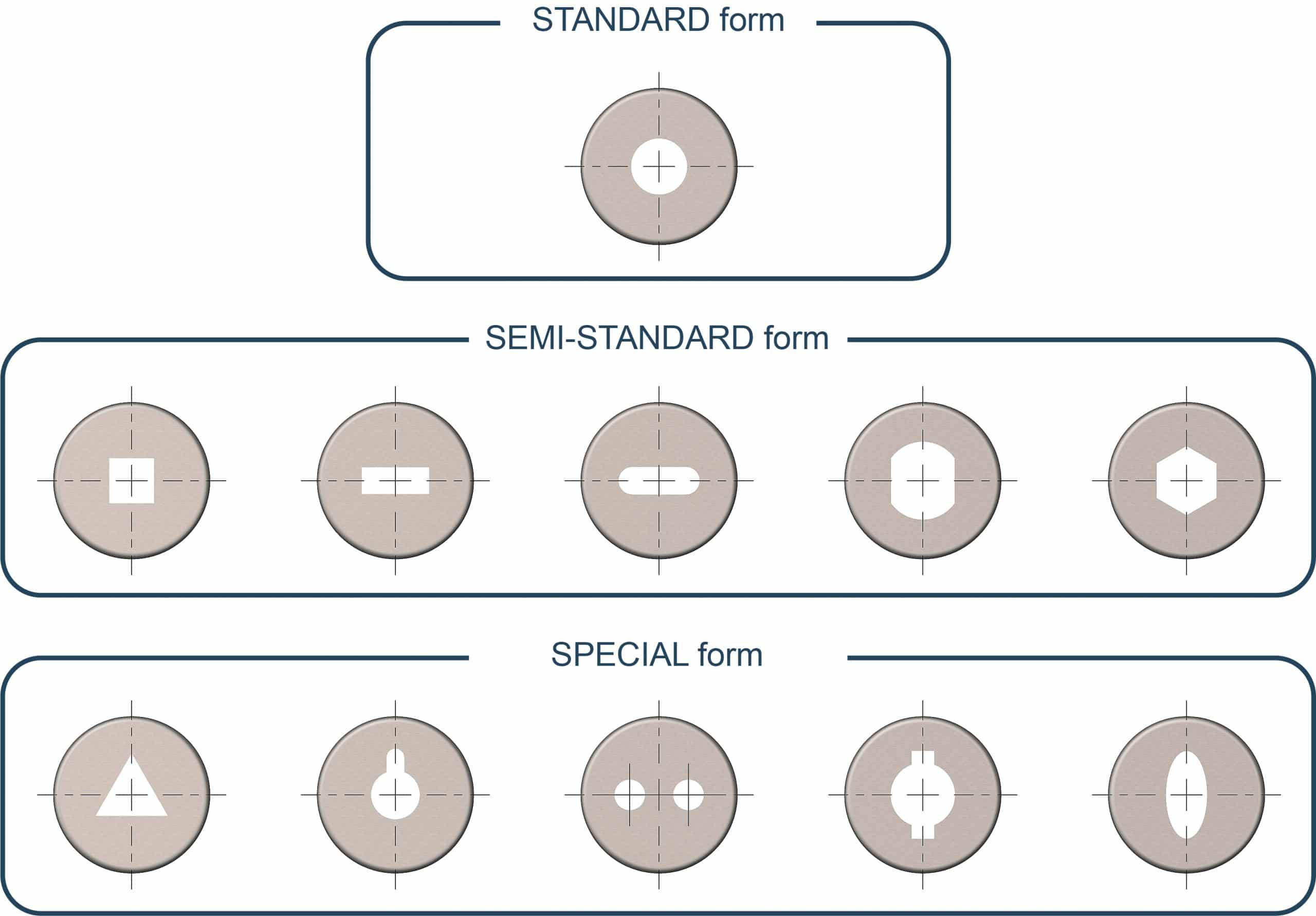

Punching forms

The punches and dies (1/2 standard and special ones) must fit within the maximum punching Ø of the corresponding unit.

The SUPRA units are press tools that are very easy to use and operate, capable to obtain a wide variety of punches shapes, but also to carry out punching, creasing, embossing, marking, bending and stamping operations.

Punching

Punching refers to the act of removing material along a closed contour.

The SUPRA units allow punching all shapes registered in a diameter of 120 mm maximum, for a material whose thicknesses are between 3 / 10 mm and 16 mm.

SUPRA punching units are suitable for working with sheet materials, profiles and tubes.

Notching

Notching denotes the action of removing material along an open outline on one side.

SUPRA units allow notching all form of material up to 10 mm thick. They are distinguished in two types, with fixed stripper known as counterplate for maximum material thicknesses of 4 mm and with mobile stripper for maximum material thicknesses of 10 mm.

SUPRA notching units adapt to the work of sheet materials, profiles and tubes.

Angle notching

Angle notching denotes the action of removing material along an outline open to two sides.

SUPRA units allow 90° or variable angle nothing of sheet materials, profiles and tubes with a maximum material thickness of 10 mm.

SUPRA notching units adapt to the work of sheet materials, profiles and tubes.

Cutting

Cutting is the action of separating the material by removing material.

SUPRA Technologies has a great know-how in the cutting of profiles and tubes. Cutting with a cutting tool is a time-consuming operation. The SUPRA cut-off units allow an important gain in productivity. Used alone or in combination, SUPRA units are suitable for the manufacture of simple and complex parts.

Shearing

Shearing is the action of cutting material without removal of material.

The SUPRA units allow the shearing of sheet, coil or bobbin up to 10 mm thick. The cutting units can be combined with other types of punching and notching units allowing the production of workpieces that would require a specific tool.