Know how

The profession of designing and manufacturing press tools is one of the most complex mechanical professions. Sheet metal working is more of an art than a science.

SUPRA Technologies designs et manufactures punching units and press tools since more than 60 years. This know-how applies to all types of work on sheet metals, tubes and profiles.

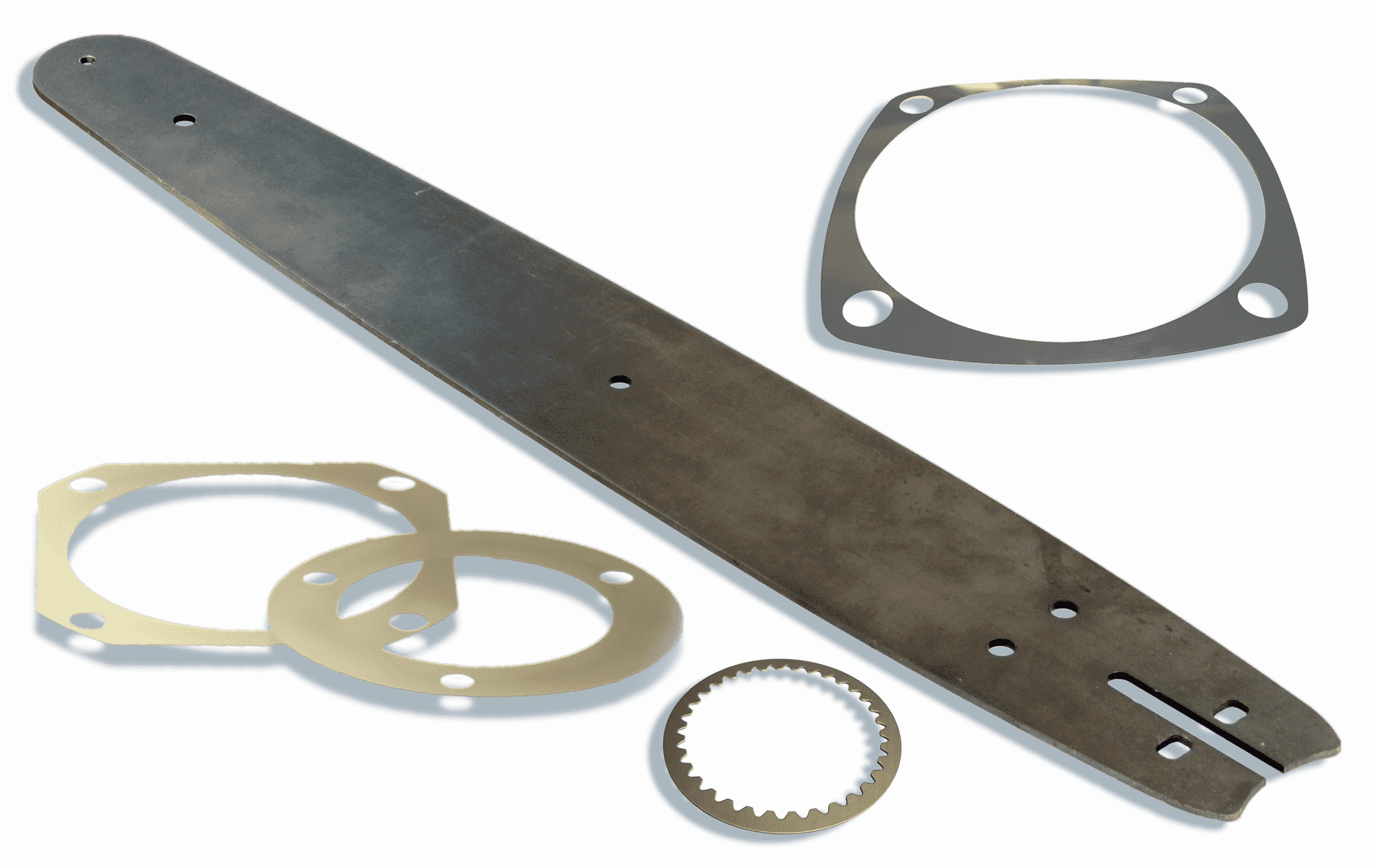

Present in all sectors of industry and crafts, here are some examples of parts made on our tools .

Parts of small and medium series

All these parts were produced on special press tools. Punching, trimming, bending, collar forming, crimping and puncturing performed on materials as diverse as steel, stainless steel, aluminum, copper, plastic and others.All of these parts are present in all sectors of the automotive, medical, building and IT industries.

Parts of great precision

These parts were made on Swiss block tools. These tools are intended for punching, cutting and trimming operations. Linear, angular and geometric accuracies are “tool precisions”, resulting in very high repeatability of the parts obtained.

Large series parts

For the production of parts in large series, progressive or following tools are the most suitable.

They allow the production of very complex pieces, which surround our daily lives.

The work of the tube

SUPRA units respond, in the vast majority of cases, to the work of the tube. Certain applications require the development of an adapted tool. It is our know-how and our role to offer you the best solution.

Stamping

Present in many industries, stamping of various parts is one of SUPRA Technologies’ know-how. Executions made on any type of steel, tools have been made for stamping thin and thick sheets.

The work of the profiles

Profiles are found in the industrial and craft sectors. Technical parts or everyday items such as windows, door sills or the spirit level used for the work, these objects come from SUPRA Technologies tools.