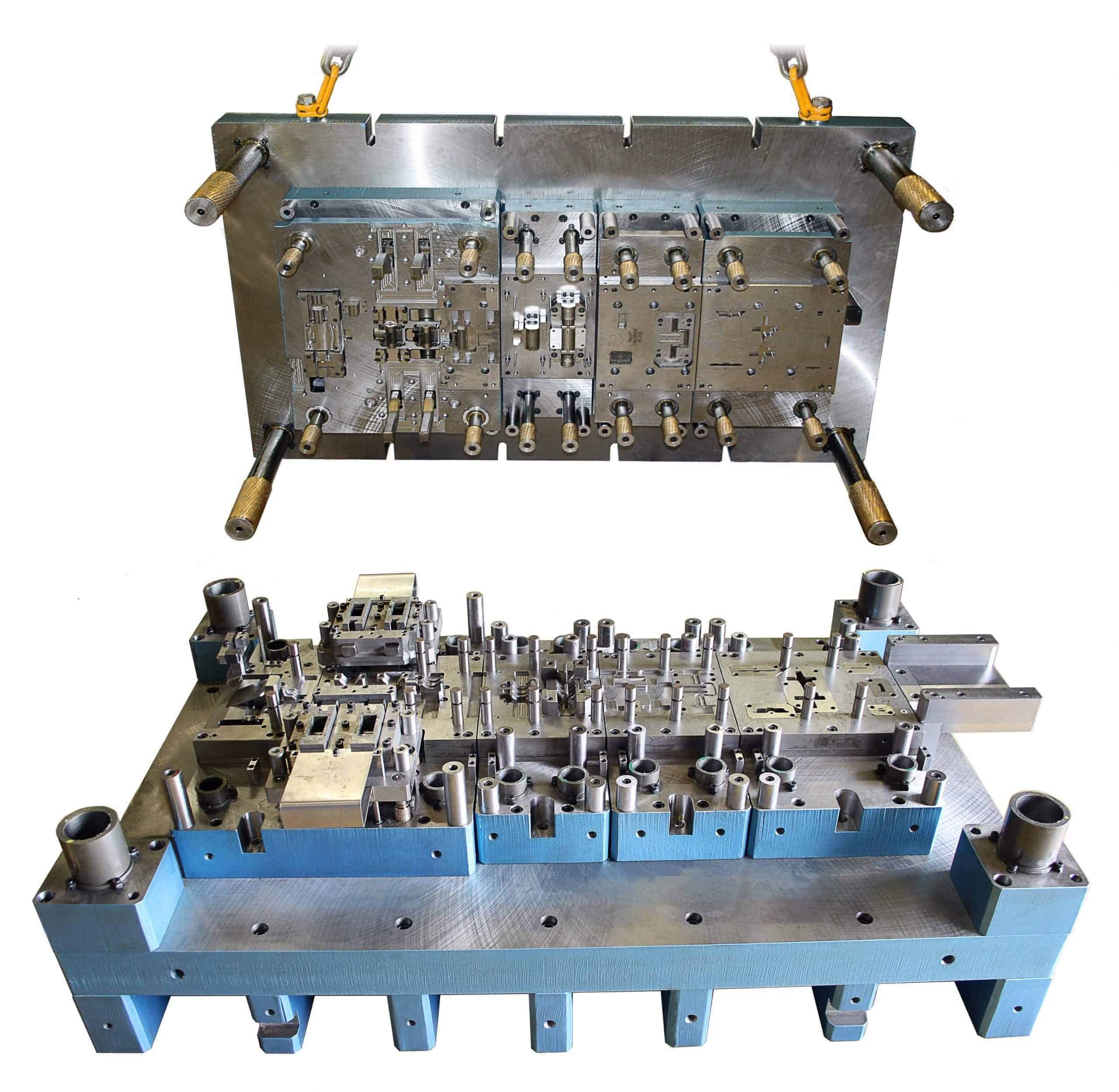

Progressive die

SUPRA Technologies, specialized in the design and manufacture of press tools, offers the study and supply of progressive dies.

Actors for more than 60 years, our progressive dies are present in all sectors of activity.

Outil progressif de marquage, poinçonnage, découpe, cambrage et emboutissage

Commonly used name among toolmakers, the progressive dies are multi-station. They belong to the family of flexible stripper tools.

Consisting of a column guided tool step, the multiplicity of stations, allows the production of parts at each press stroke while combining different functions.

The combination of the functions of punching, marking, cutting, routing, cambering, lifting, rolling, bending, stamping, punching and creasing allows the production of more or less complex parts. Despite these advantages, the progressive die can only be considered for the production of parts in large series.

These tools can be made autonomous. In this case, no mechanical connection to the press ram is required. The tool is lifted up by wire or gas springs, which saves time in setting up the tool under press.

The use of progressive tools requires a supply of material in strip or reel form.

Feeding, a means of feeding the raw material into the tool, is automatic. These automatic devices ensure the advane of the strip by pushing or pulling at a determined pitch corresponding to the tooling. They are tool-independent and managed by the press. The tooling has a control device allowing the re-centring of the strip for each function.

The evacution of the parts generated by the tool can be recovered at its end opposite to the material inlet, or underneath, commonly referred to as « the passage through ».

Knockouts or waste from punching and cutting operations are removed from underneath. A scrap outlet is to be taken into account either through the evacuation hole provided through the press table or by placing cleats between the lower block of the tool and the press table.