Combination cutting tool

SUPRA Technologies has been making combination cutting tools for many years. They allow the production of very high quality parts. Intervening in the design of press tools for all sectors of activity, the SUPRA Technologies teams are at your disposal in their advisory role and provide you with the solution adapted to your needs.

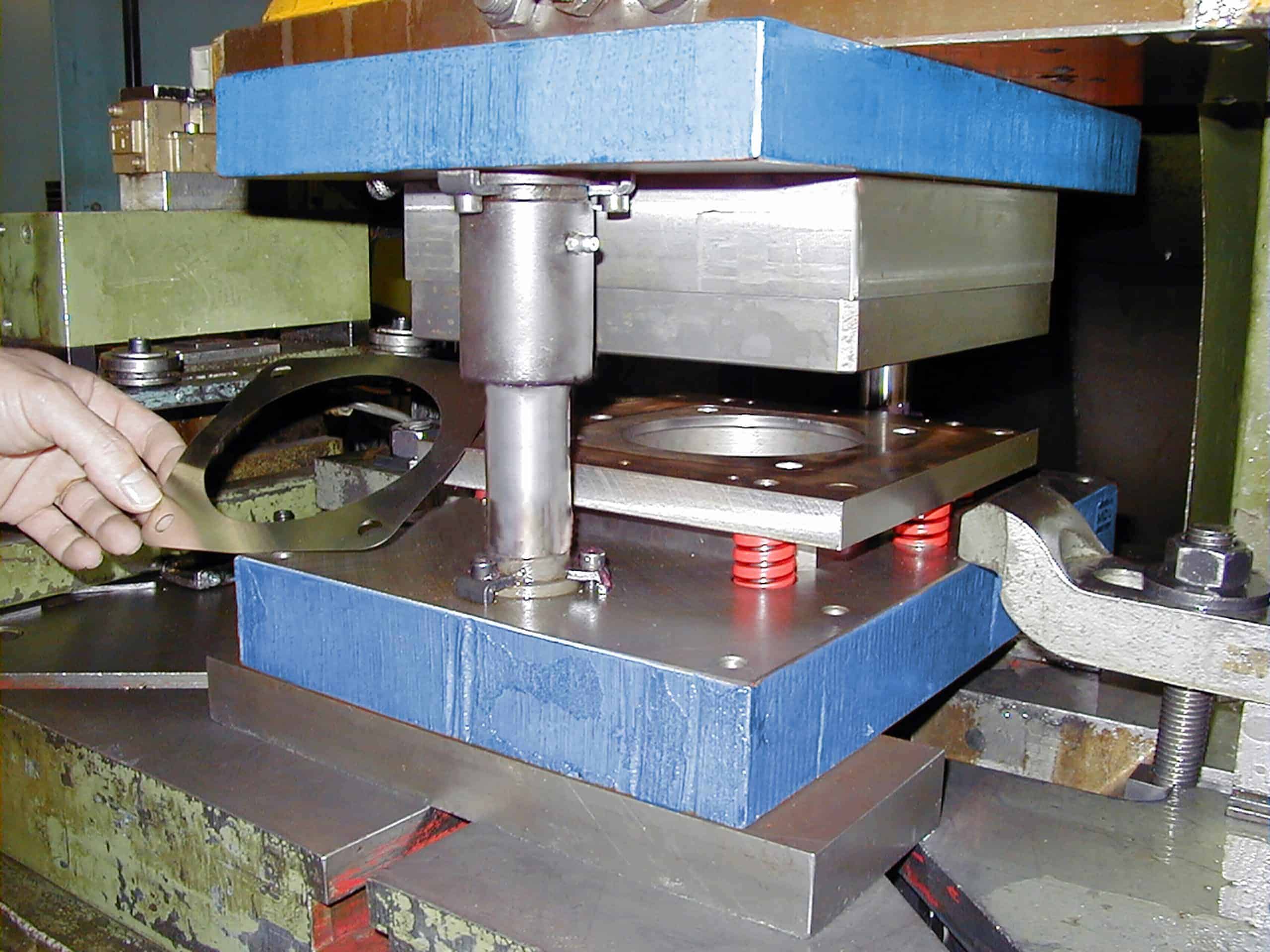

Combination cutting tool

Combination cutting tools, also known as Swiss tools, are exclusively reserved for cutting and punching. Single-position tools, these operations carried out simultaneously, make it possible to obtain a part in one press stroke. The resulting pieces are highly accurate and repeatable.

Mounted in a 2 column guided tool step, the architecture of this type of tool is as follows : positioned on the lower sole, the punch has the function of trimming the part. It can be used as a matrix for the punching operations to be carried out. The stripper, which is elastic, is also located at the bottom, acting upwards. At the top is the routing matrix. Located in the center of the die, the die bottom extracts the part. Through this die bottom, the punches do their job through the lower punch, which in this case becomes punch / die.

The combination cutting tool has the advantage that it can be used automatically from reel material, strips or pre-cut blanks. In the case of automatic operation, the pitch is set by the feed unit itself or, in the manual version, by a mechanical stop.

These tools can be made autonomous. In this case, they do not require a mechanical connection to the press ram. The tool is lifted by wire or gas springs, which saves time in setting up the tool under press.

Knockouts or waste from the punching operation are removed from underneath. A scrap outlet is to be taken into account either through the evacuation hole provided through the press table or by placing cleats between the lower block of the tool and the press table.

Despite these great qualities, the combination cutting tool places the finished part on the belt. It is necessary to carry out a manual evacuation operation or to use an automated system. This involves a press with a stroke of 80 to 100 mm to promote evacuation.