PRECONIZATION

The durability of a tool depends on the care you give it.

A frequent sharpening will extend the life of your tool, will reduce the volume you need and will produce holes of better quality. A tool lately or not sharpened, will need additional pressure on the cutting parts. These ones deteriorate faster and faster. The cut quality will also be affected with the appearance of important burrs and a less frank cutting attack.

Therefore, frequent sharpening is the most economical way to achieve a quality result.

Incorrect setting of your press or a foreign body in the tooling can cause important damage to your machine.

To optimize the performance of your SUPRA tools, we recommend the following maintenance procedure :

- Adjust the bottom « dead point » of your presse (Height Closed Tool : HOF). This must in no case be lower that the HOF indicated on the SUPRA unit or on the tool identification plate. Improper adjustment of your press can lead to total and irremediable destruction of your tools and with a significant risk of causing damage to the press.

- Closed tool Height (HOF) should be checked periodically. This frequency depends on the rate and duration of the strike.

- Regularly check that all the elements of your unit or tool are properly fixed. An incorrectly tightened fixing screw may fall into the tool. When closing it in press, the damage could be very significant, see the total destruction of the tools.

- Keep your unit or tool clean.

- Regularly grease all moving parts of the tools after thorough and careful cleaning.

- If necessary, replace worn components such as springs and retainers, if necessary.

- Check the height of the free springs. If this height is lower than their expected lengths, change them, because this is a sign of tiredness and a risk of breakage which will lead to other deteriorations

- Thoroughly check the condition of your punches and dies regularly (no wear or defect)

- Punches and dies must be sharpened regularly. Grinding 1/10 of the cutting faces, without waiting for a defect, increases the durability of your unit or tool. Consider compensating for the rectified heigth on the punch and on the bed by placing a compensating sharpening wedge of this raised height.

- After sharpening, the punches and dies must be demagnetized, thoroughly cleaned and lubricated.

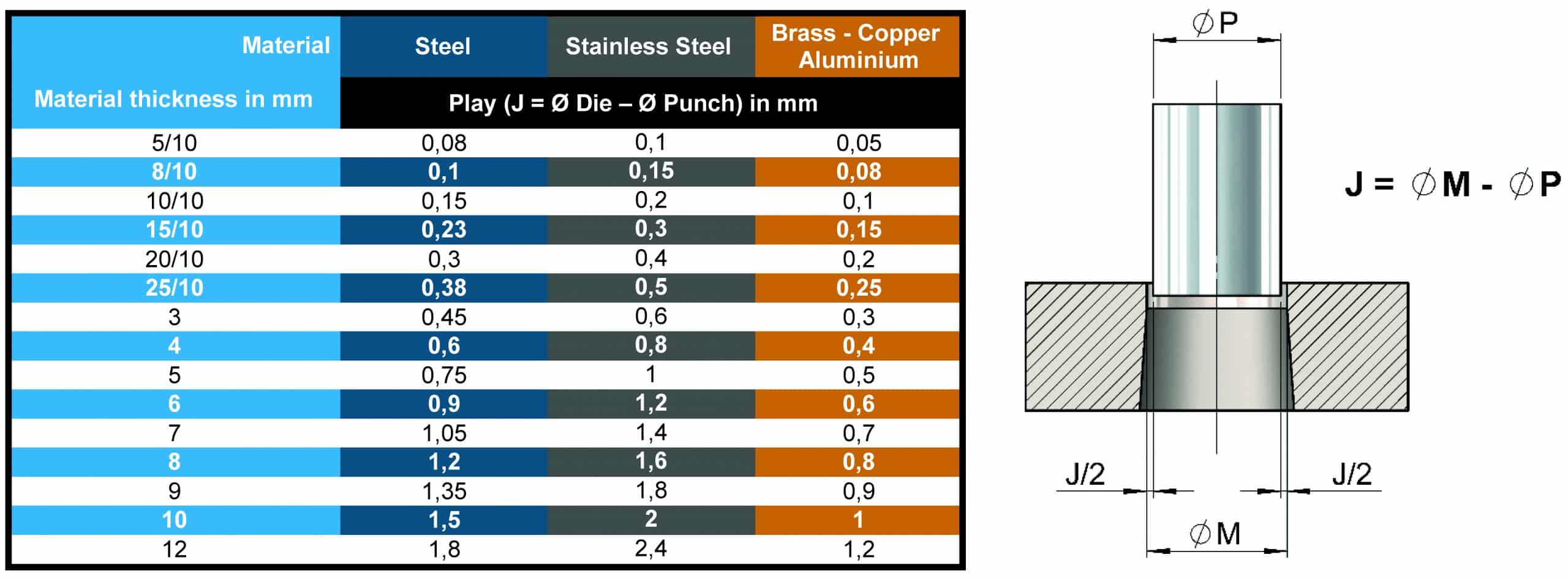

- Meticulously check backlash between punches and dies. The sets are adapted to the thickness and grade of the material. Too much play automatically results in a bad cut and a large burr. A too tight play will cause a deterioration of the punch prematurely by a dulling of its cut stop and the appearance of brilliance. Similarly on the die, the cutting stop will be quickly blunted and the internal pressures generated by the punching operation will be very important with the risk of bursting it.

Recommended play between punch and die in mm at Ø :